Sometimes the testing phase feels complicated

We believe in the value of your device. Let’s clear the path to market with the packaging testing it deserves.

Package Testing services

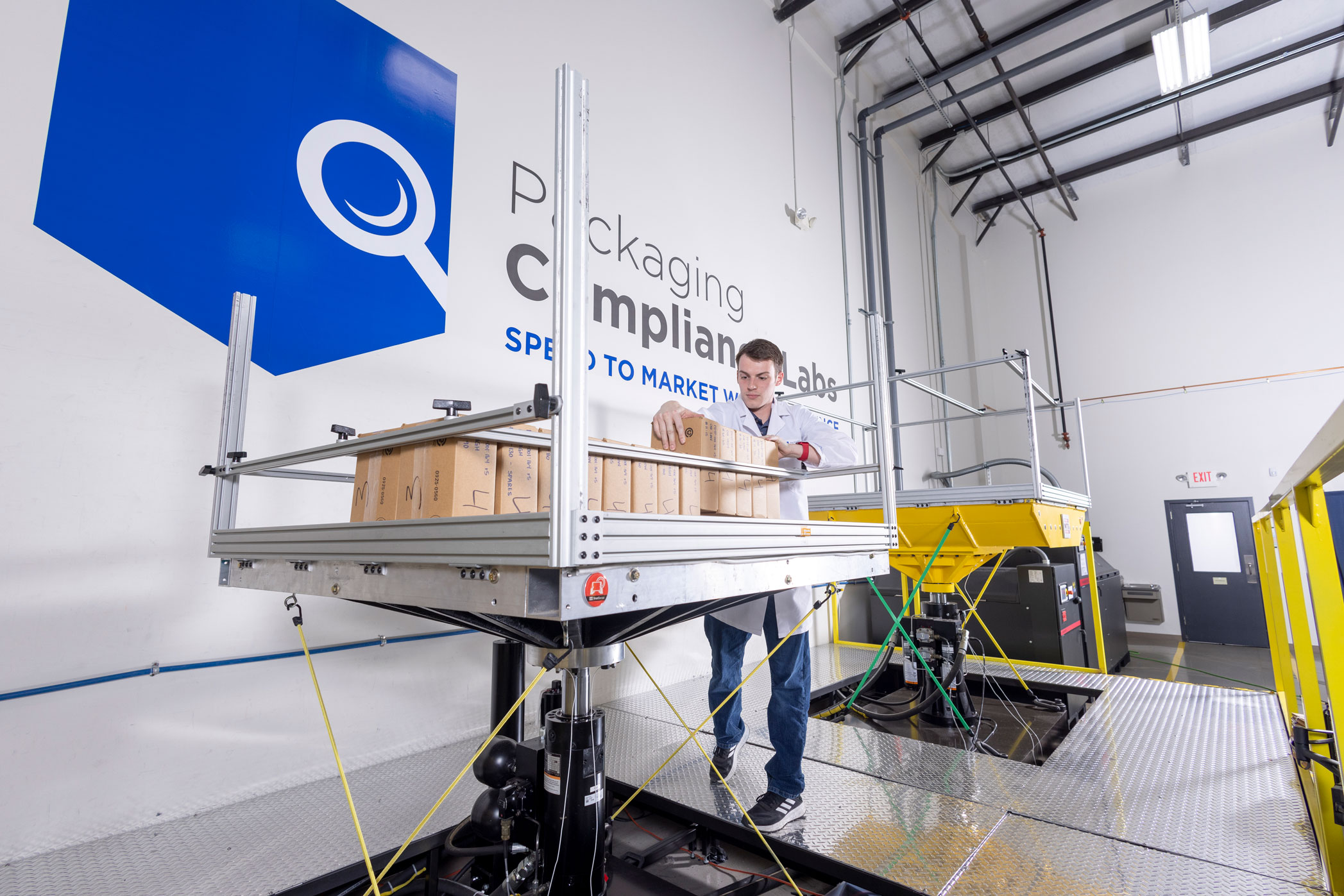

Transit Testing

Prove that your packaging will arrive with the sterile barrier intact.

Meet the recognized guidelines for terminally sterilized medical devices. From environmental preconditioning to final drop testing, our medical device transit testing procedures deliver precise, reliable results, now.

Shelf-Life Testing

Prove your packaging can withstand the test of time.

Accelerated testing in conjunction with real-time aging verifies that your device can withstand the test of time. Leverage our 5,000 cubic feet of accelerated aging capacity.

Sterile Barrier Package Integrity

Maintain sterility to your device’s intended use.

Every effort in packaging your medical device shares the goal of maintaining sterility to its intended medical use. Integrity testing is part of every sealer qualification, shelf-life and transit validation. It is the ultimate pass or fail of every validation. We are an independent third-party partner with a proven track record. Our test methods have been validated, so you can count on consistent, quality results.

Material + Label

Confirm strength and durability.

Unique Device Identification and EU MDR initiatives have brought an increased focus on labeling. It is now more important than ever to confirm label durability and legibility. To address these specialized considerations, we offer a number of test methods to set your validation efforts up for success.

Services

Explore more PCL Services