Label Adhesion Test

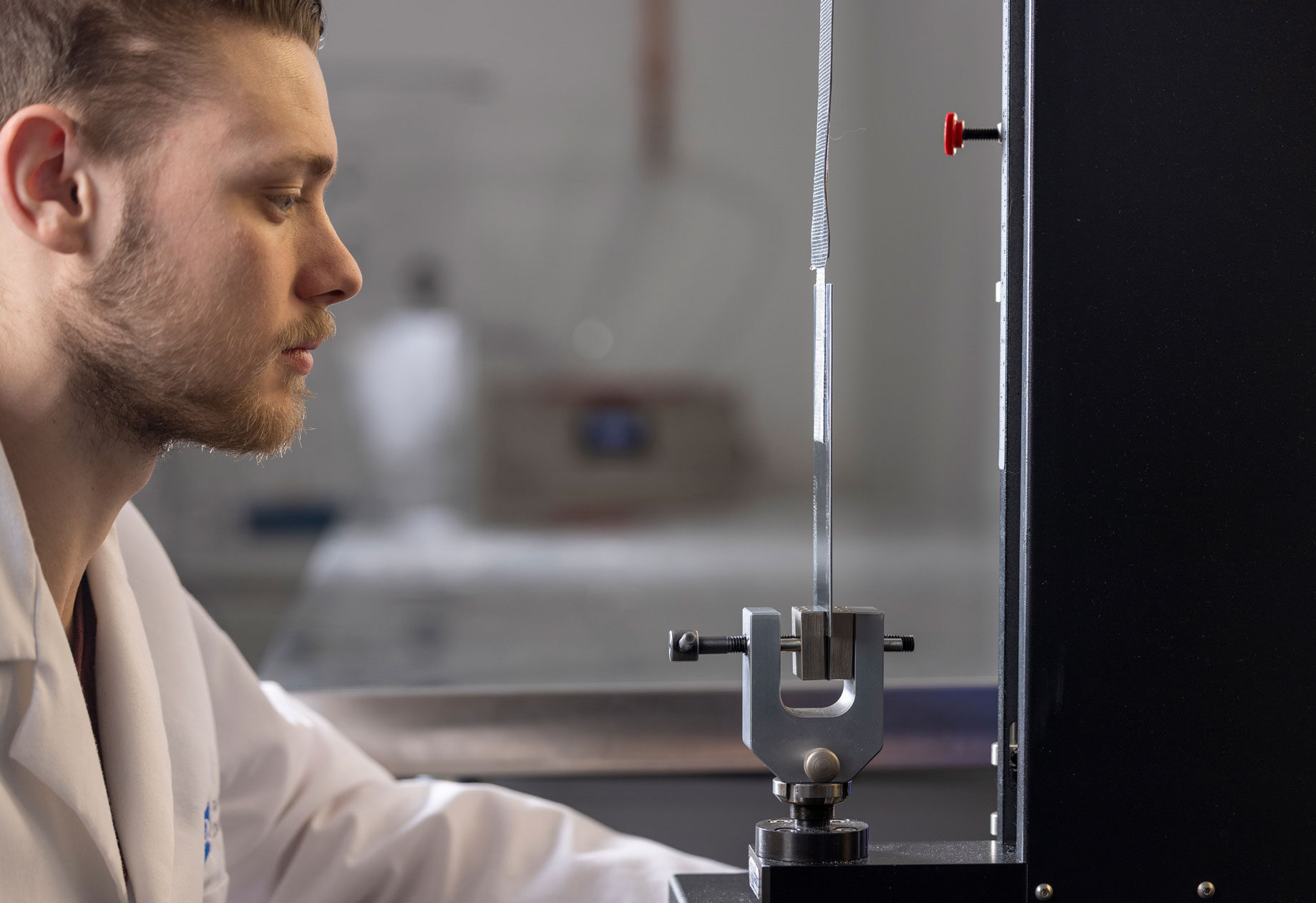

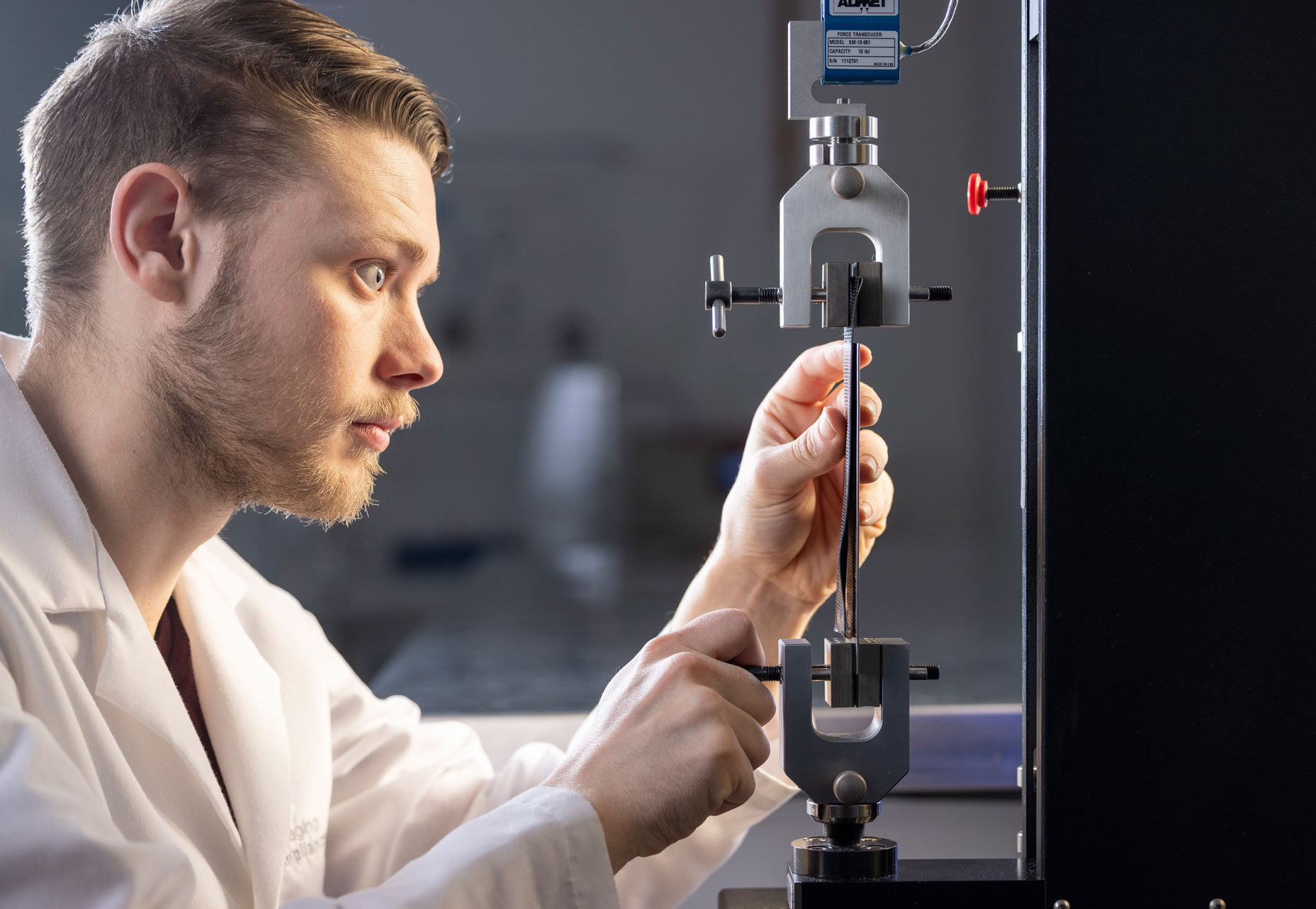

The Label Adhesion test is intended to measure the strength of the adhesive material used in the construction of a label. The test is performed by cutting a 1″ specimen from the label. The release liner is removed and then the label is affixed to a stainless steel plate. Constant pressure is applied to ensure even and repeatable application from sample to sample. The free tail of the specimen is then bent back 180 deg and secured in the upper jaw of a tensile tester. The steel plate is affixed to the lower jaw of the tensile tester. The tensile tester then separates the label from the steel plate at a constant speed.

A load cell measures the force required to fully separate the label from the underlying steel plate to which it is affixed. Other variations on this method include a 90 degree peel orientation.

Industry Application

This peel adhesion test evaluates the ability of a label to stay attached to a given substrate. It may be used to compare one label material to another, or a label’s ability to maintain adhesion over time through accelerated aging.

Frequently asked questions

What kind of data does label adhesion testing provide?

These test methods cover the measurement of the peel adhesion of pressure-sensitive labels and tapes, and provides a means of assessing the uniformity of the adhesion, and the strength of the adhesive bond, of a given type of pressure-sensitive adhesive.

When would label adhesion test data be useful?

These test methods are tools for quality assurance use. Given specific pressure-sensitive labels and a requirement in terms of the minimum or maximum peel value expected, the data from the test can be used to verify quality, monitor trends over time, and to evaluate the impact of any potential changes to material of construction as part of a label change.

Which label testing standard does label adhesion testing fall under?

ASTM D3330, the Standard Test Method for Peel Adhesion of Pressure Sensitive Tape, can be followed when testing label adhesion.