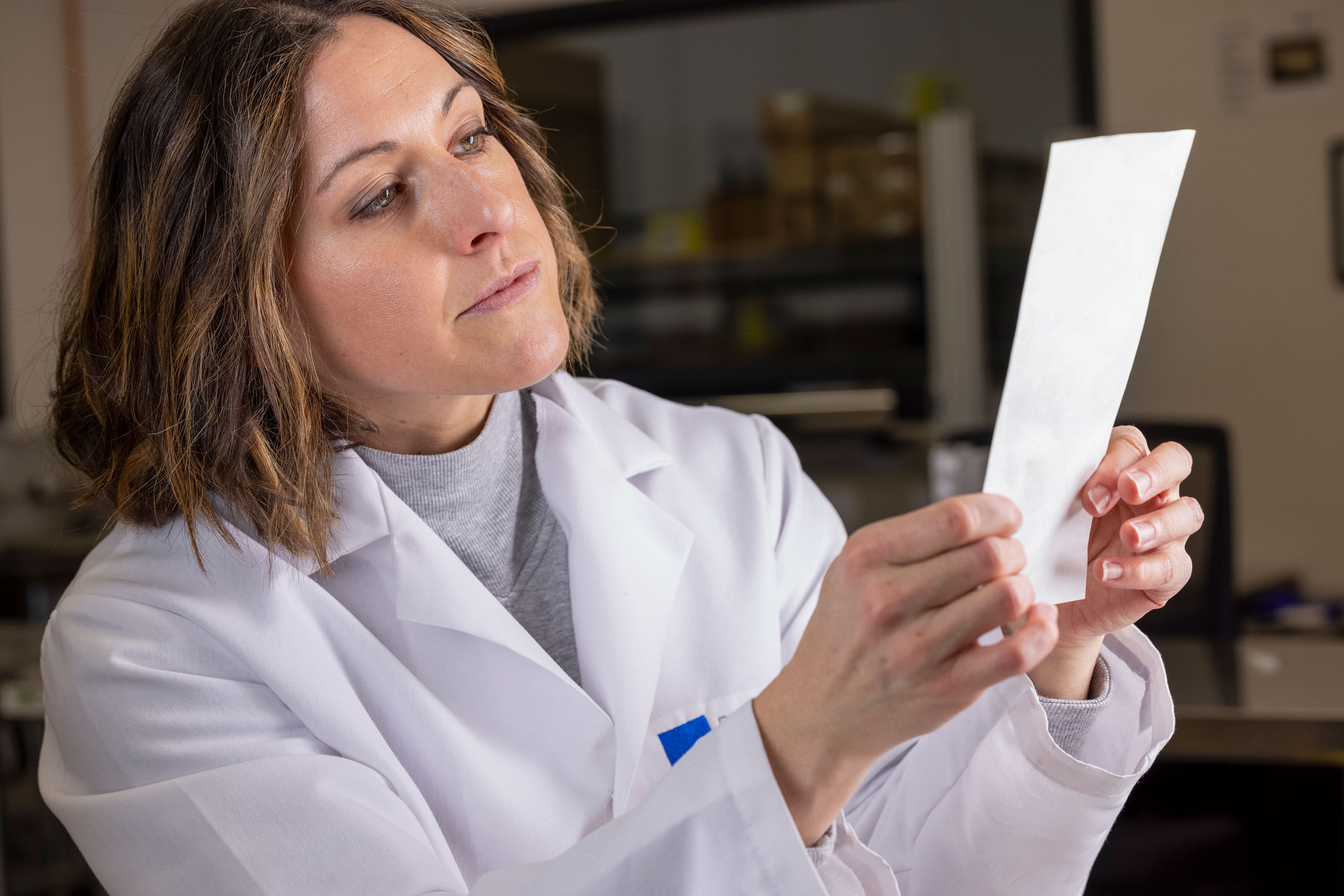

Visual Inspection Test

This ASTM visual inspection method is a non-destructive visual examination of a sterile barrier closure seal to identify any potential seal defects, such as channels, wrinkles, folds, voids, or other visually-evident defects of the sterile barrier. The method is applicable to both flexible and rigid packages with a minimum of one transparent side so that the seal is in plain view. The effectiveness depends on factors such as the size of the channel, the materials used in the packaging, whether or not magnification is used, type of adhesion used, and the visible contrast between sealed and unsealed areas.

Industry Application

Visual inspection for sterile barrier integrity is an important feature of all packaging validation activities – including process validation, transit validation, and shelf life validation. It would be conducted alongside other package and seal integrity tests, such as dye leak testing, bubble leak testing, or seal strength testing. Visual inspection is also routinely incorporated into production processes as a 100% visual inspection of each sealed package immediately after the sealing operation and before the packaged products are introduced to cartons or boxes.

Frequently asked questions

What is Visual Inspection Testing per ASTM F1886?

Testing for the visual inspection standard ASTM F1886 is typically performed from approximately 12-18"" with the unaided eye, for approximately 3-5 seconds. The user is seeking to identify any potential defects of the seal, such as channels, voids, wrinkles, product caught in the seal, or any other visually evident breaches of the sterile barrier. The ASTM F1886 round robin study demonstrated efficacy down to a defect size of 0.003 inches width with 60% reliability. This test method is applicable to packages with at least one transparent side so that the seal area may be clearly viewed.

What is the purpose of the visual inspection test?

This test method provides a qualitative visual inspection method to evaluate the appearance characteristics of unopened, intact seals to determine the presence of defects that may affect the integrity of the package.