A

AA – Accelerated Aging

Storage of samples at an elevated temperature in order to simulate real-time aging in a reduced amount of time.

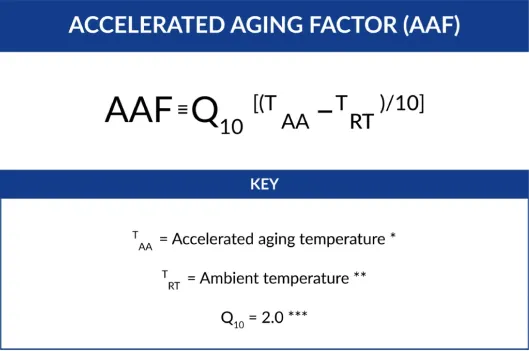

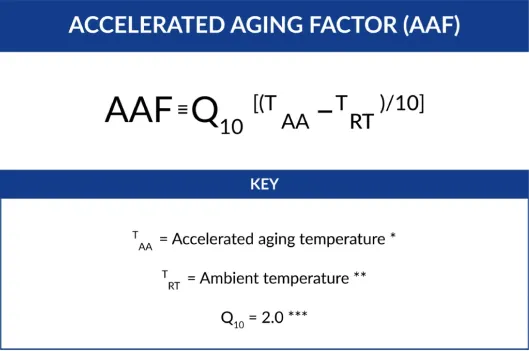

AAF – Accelerated Aging Factor

An estimated ratio of the time needed to achieve the same level of physical property change as a sterile barrier system stored at real time conditions.

AB – Accredited Body

AFAP – Risk reduced As Far As Possible

AL – Assurance Level

AL – Assurance Load

ASR- American Systems Register

ASTM D4169

Standard Practice for Performance Testing of Shipping Containers and Systems. This practice provides a uniform basis of evaluatin–, in a laboratory-- the ability of shipping units to withstand the distribution environment. This is accomplished by subjecting them to a test plan consisting of a sequence of anticipated hazard elements encountered in various distribution cycles.

Attribute Testing

Attribute testing results in a ‘pass/fail’ determination and does not provide numerical output. Bubble leak testing and visual inspection are examples of attribute testing because they result in a pass/fail.

B

B/F – Bacteriostasis Fungistasis

BA – Broadly Acceptable Risk

BET – Bacterial Endotoxin – uses LAL

BI – Biological Indicator

During sterilization, to test whether the EO completely sterilized the shipper, the BI is marked to show there is a bio-organism that should be sterilized by EO. A box will usually be indicated (on a specific side of the box) with a label identifying the control sample in the sterilization test.

BL – Bubble Leak

BOM – Bill Of Material

Bubble Leak Testing

ASTM F2096 Standard Test Method for Detecting Gross Leaks in Packaging by Internal Pressurization. This test method can detect gross leaks in packaging as small as 250 microns. The package is inflated under water to a predetermined pressure and is observed for a steady stream of air bubbles that would indicate a failure.

Burst Strength Testing

ASTM F1140 Standard Test Method for Internal Pressurization Failure Resistance of Unrestrained Packages. The test methods within this standard increasingly pressurizes the package until it fails. These test methods provide a rapid means of evaluating tendencies for package failure when the package is exposed to a pressure differential.

C

CA/PA – Corrective Action / Preventative Action

CAB – Conformity Assessment Body

CAR – Corrective Action Report

CD – Critical Dimension (circled)

CD – Cross Direction

CFR – Code of Federal Regulation

CFU – Colony Forming Units

Class I Medical Device

Low risk device i.e. bandages

*The EU has similar classes of severity with Class I as the lowest risk

Class II Medical Device

Intermediate-risk devices

*The EU has similar classes of severity with Class I as the lowest risk

Class III Medical Device

High-risk devices (that sustain life i.e. cardiovascular devices)

*The EU has similar classes of severity with Class I as the lowest risk

CM – Contract Manufacturer

COD – Certification Of Destruction

CompliancePack™

or CPack™, is PCL’s ISO 11607-compliant pre-validated packaging platform.

CS – Component Specification

CSR – Cellulose-based wrapping material i.e. CSR wrap

CV – Cleaning Validation

D

DFMEA – Design Failure Mode and Effect Analysis

DHF – Device History Files

DHR – Device History Records (Master list)

DL – Dye Leak

DOE – Design Of Engineering/Experiment

DOT – Hazardous Material Qualification

DV – Design Verification (Transit)

DW – Double Wall

Dye Leak Testing / Dye Pen

ASTM F1929 Standard Test Method for Detecting Seal Leaks in Porous Medical Packaging by Dye Penetration. This test method detects breaches as small as 50 microns in a package seal edge. A dye solution is applied to the seal to be tested for leaks.

E

ECT – Edge Crush Test

eIFU – electronic Instruction for Use

Environmental Conditioning

ASTM D4332 Standard Practice for Conditioning Containers, Packages, or Packaging Components for Testing. This practice provides standard and special conditioning and testing atmospheres that may be used to simulate particular field conditions that a container, package, or packaging component may encounter during its life or testing cycle.

EO – Ethelene Oxide sterilization

EOI – Equipment Operating Instructions

ERP – Enterprise Resource Planning (NetSuite)

EU – Endotoxin Units

F

FAI – First Article Inspection

FEAS – Feasibility

FG – Finished Good

FIC – Formal Information Collection

G

GA – Gage

GLP – Good Laboratory Practice

GMP – Good Manufacturing Practice

GRMS – Gravity Root Mean Square (unit of measure)

GS1 – General Specifications (Barcode reading)

GTIN – Global Trade Item Number

I

IFU – Instruction for Use

ILS – Inter-Laboratory Studies

INT – Risk Intolerable

IOPP – Institute of Packaging Professionals

IP – Inspection Plan

IQ – Installation Qualification

ISO – International Organization of Standards

ISO 11607: International Standard for Packaging Terminally Sterilized Medical Devices

This document specifies requirements for the design of sterile barrier systems for terminally sterilized medical devices, the basic attributes required of materials, and design validation requirements.

ISO 13485

International Standard for Medical Devices – Quality management systems – requirements for regulatory purposes. This standard ensures consistent design, development, production, installation, and delivery of medical devices.

ISTA – International Safe Transit Association

ITM – Internal Test Method

L

Label Adhesion

ASTM D3330 Standard Test Method for Peel Adhesion of Pressure Sensitive Tape. This test method covers the measurement of the peel adhesion of pressure-sensitive tape. It provides a means of assessing the uniformity of the adhesion of sensitive tape.

LAL – Limulus Amebocyte Lysate

LB – Label Specification

LOA – Level of Assurance

LOD – Limit Of Detection

LOI – Laboratory Operating Instruction

LOQ – Limit Of Qualification

LS – Labeling Spec

LSL – Lower Spec Limit

M

MD – Machine Direction

MDM – Medical Device Manufacturer

MDMA – Medical Device Manufacturer Association

MDPTC – Medical Device Packaging Technical Committee

MVTR – Moisture Vapor Transmission Rate

N

NC – Non-Conformance

Nom – Nominal

Non-Attribute Testing

Non-attribute testing provides an output that has a value. For example, peel strength testing pulls apart the two pieces of material that make a seal and outputs a value.

NPD – New Product Development

O

OEM – Original Equipment Manufacturer

OQ – Operation Qualification

OTR- Over The Road

P

Packaging Compliance Medical (PCM)

An ISO 13485:2016 certified contract manufacturer (CM) that specializes in small-volume production.

PCL – Packaging Compliance Labs

PCM – Packaging Compliance Medical

PEEK – Polyetheretherketone

Peel Strength Testing

ASTM F88 Standard Test Method for Seal Strength of Flexible Barrier Systems. Peel strength testing measures the strength of seals on rigid and flexible materials.

PFMEA – Process Failure Mode and Effect Analysis

PN – Part Number

PO – Purchase Order

PQ – Performance Qualification

Process Validation

A process validation verifies that equipment operates as intended. This includes ensuring that the sealing and forming processes are repeatable and reliable.

PSI – Pounds per Square Inch

PV – Process Verification

Q

QMS – Quality Management System

QR – Quick Response

R

RPN – Risk Priority Number (i.e. Severity x Probability = RPN)

RT – Router

RTA – Real Time Aging

Storage time of samples at ambient conditions.

RW – Rework

S

SAL – Sterility Assurance Level

SBS – Sterile Barrier System

SCAR – Supplier Corrective Action Requests

Shelf Life Validation

Shelf life testing (also known as stability or aging) testing demonstrates the ability of the packaging system to maintain sterile integrity and other key performance properties over time.

SIP – Sample Item Portion

SKU – Shop Keeping Unit

SLV – Shelf-Life Validation

SME – Subject Matter Expert

SN – Study Number

SS – Seal Strength

Sterile barrier package integrity / Sterile barrier system integrity

Testing that establishes the capability of the sterile barrier system to maintain sterility.

Sutherland Rub

ASTM D5264 Standard Practice for Abrasion Resistance of Printed Materials by the Sutherland Rub Tester. This test method determines the abrasion resistance of printed materials (such as labels, carton boxes, inserts, and other packaging materials) that have graphics printed on a flat substrate.

SV – Sterile Validation

SW – Seal Width

SW – Single Wall

T

TL – Tooling

TMI – Test Method Introduction

TMV – Test Method Validation

TOC – Total Organic Carbon

TOPS – Total Optimization Packaging Software

TPS – Test Parameter Sheet

TPU – Thermoplastic Polyurethane

Transit Validation

Transit testing challenges the packaging system’s ability to withstand the forces of sterilization, handling, and distribution while maintaining a sterile barrier and other important characteristics.

U

UDI – Unique Device Identifier

Underwater Vacuum Leak

ASTM D3078 Standard Test Method for Determination of Leaks in Flexible Packaging by Bubble Emission. This test method covers the determination of gross leaks in packaging containing a headspace gas.

Usability Evaluation

ISO 11607-1 was updated to include Usability Evaluation for Aseptic Presentation (section 7). This revision requires medical device manufacturers to assess their sterile barrier system designs while considering healthcare professional inputs.

USL – Upper Spec Limit

USP – United States Pharmacopeia

V

VIS – Visual Inspection

Visual Inspection Testing

ASTM F1886 Standard Test Method for Determining Integrity of Seals for Flexible Packaging by Visual Inspection. This test method provides a qualitative visual inspection method to evaluate the appearance characteristics of unopened, intact seals to identify defects that could affect the integrity of the package.

VOE – Verification of Effectiveness

W

WFI – Water For Injection

WI – Work Instruction

WIP – Work In Progress

WO – Work Order