ASTM D4169 Transit Simulation

ASTM D4169 is an FDA-recognized consensus standard for conducting a transit simulation study for sterile barrier medical device packaging systems. There are other recognized standards such as ISTA 3A, however the ASTM D4169 standard is the most common choice amongst the medical packaging industry.

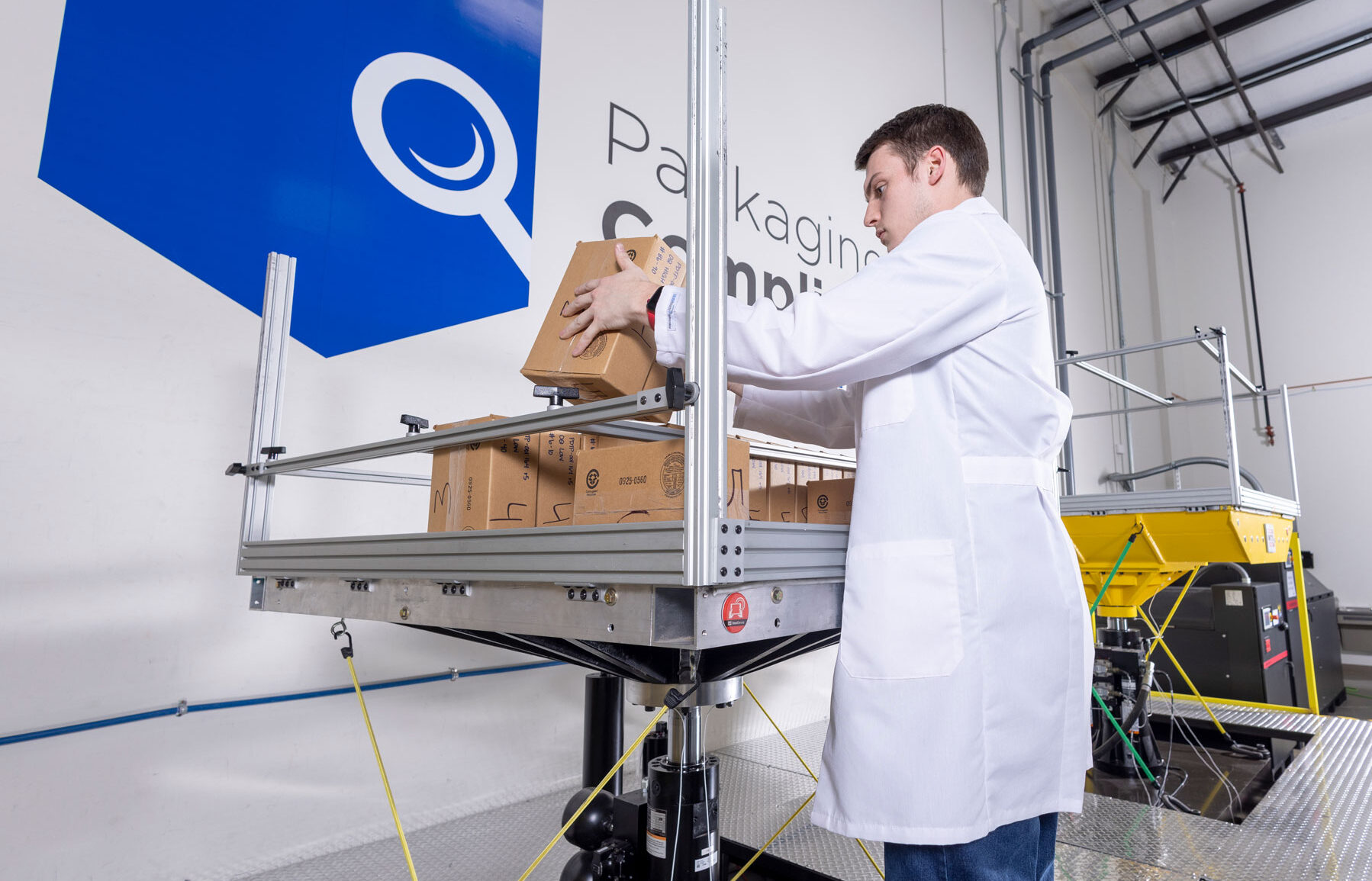

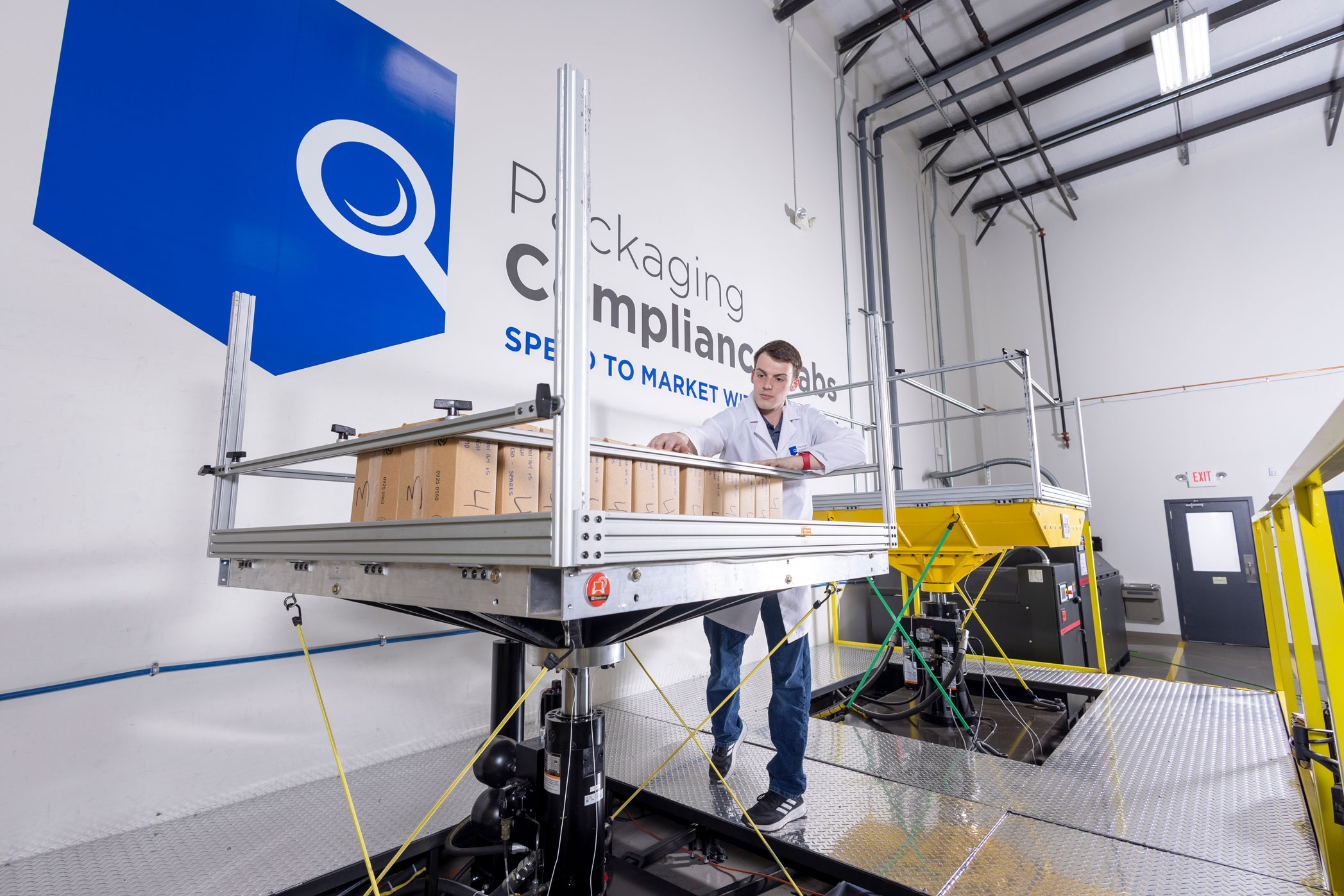

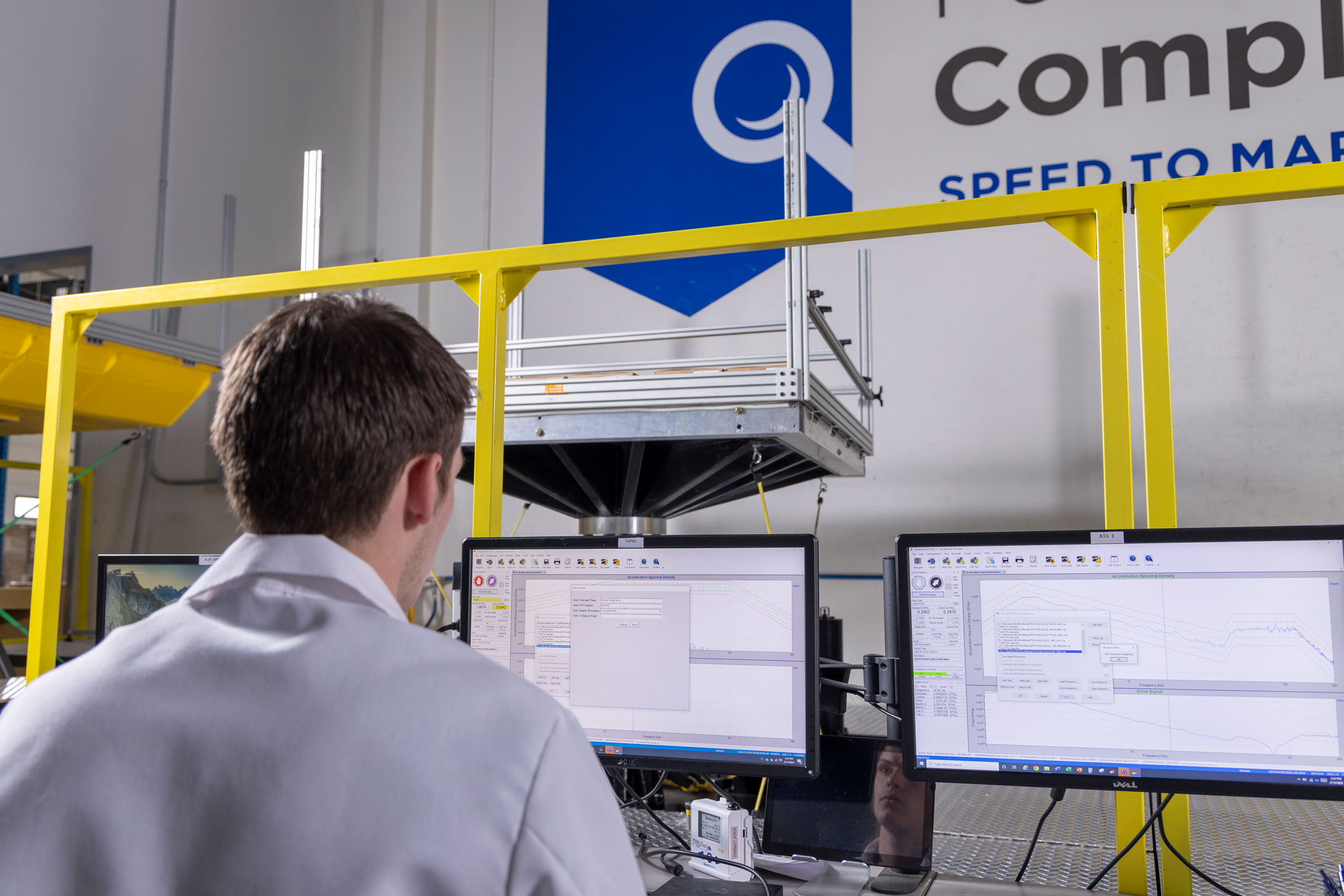

A transit study typically includes drops, compression, vehicle vibration, high altitude (low pressure), and shock testing. These simulate the dynamic hazards that a packaged product might encounter during shipment in the real world. Our facilities allow us to customize test plans, and we can accommodate nearly any transportation simulation testing scenario.

Industry Application

Distribution testing can be used to simulate a wide variety of distribution scenarios, such as unitized loads and LTL. Because the small parcel environment most often represents the “worst case” scenario, it tends to be the most common choice for sterile barrier packaging validation. These distinctions are outlined within the ASTM D4169 standard as described by the term “Distribution Cycles”, with “Distribution Cycle 13” (DC13) being the worse case small parcel distribution environment.

Passing Distribution Validation is a requirement of sterile medical device packaging. This data must be included with your 510k documentation when you submit to the FDA.

ASTM D4169 has 18 distribution cycles within it. We select the one that is most appropriate based on what you think your packaging will endure during the distribution cycle in the real world. The most common distribution cycle is DC13, which is a truck and air profile. Within DC13, there are 7 tests. Those are:

DC13 Test Schedule Sequence:

Schedule A: Handling (Drop Testing)

Schedule C: Stacking (Compression Testing)

Schedule F: Loose-Load Vibration (Vibration Testing)

Schedule I: Low Pressure (Aircraft Simulation)

Schedule E: Vehicle Vibration (Vibration Testing)

Schedule J: Concentrated Impact (Dart)

Schedule A: Handling (Drop Testing)

As you can see, transit testing begins and ends with drop testing with a lot of vibration testing in the middle. The order of these events is to simulate what a distribution path is like in the real world. The drops at the beginning simulate sorting at the distribution facility. Vibrations and compressions represent the package traveling in the back of a shipping truck and having packages stacked on top of it. The drop at the end simulates the final drop off, wherever that might be!

Just like there are multiple distribution cycles, there are three assurance levels. Assurance level 1 is the most extreme and 3 being the least extreme. Medical device companies almost always run assurance level 1, with a few exceptions if they have the technology to track the distribution cycle of their samples. If we are making a recommendation to a medical device company with a sterile device, we will always recommend AL1.

Frequently asked questions

What is ASTM D4169 Transit Simulation?

ASTM D4169 testing is a common standard for distribution simulation testing that includes vibration/shock, drop testing. ASTM D4169 simulates an extreme shipping environment to appropriately challenge many types of packaging systems.

Why is Transit Simulation required for medical device packaging validation?

If a medical device manufacturer is bringing a new device to market, evidence of successful distribution testing is an important part of most 510k submissions. Transit simulation provides data that proves a sterile barrier system can withstand the extreme rigors of distribution.

How many shippers should I send for testing?

The sample size for your transit testing study is determined by the purpose of the study, the risk associated with your device. Is your transit study for R&D purposes, or is it for your full packaging validation that you intend to submit to the FDA for your 510K? These are factors that will help you determine what your sample size should be.