Peel Strength Test

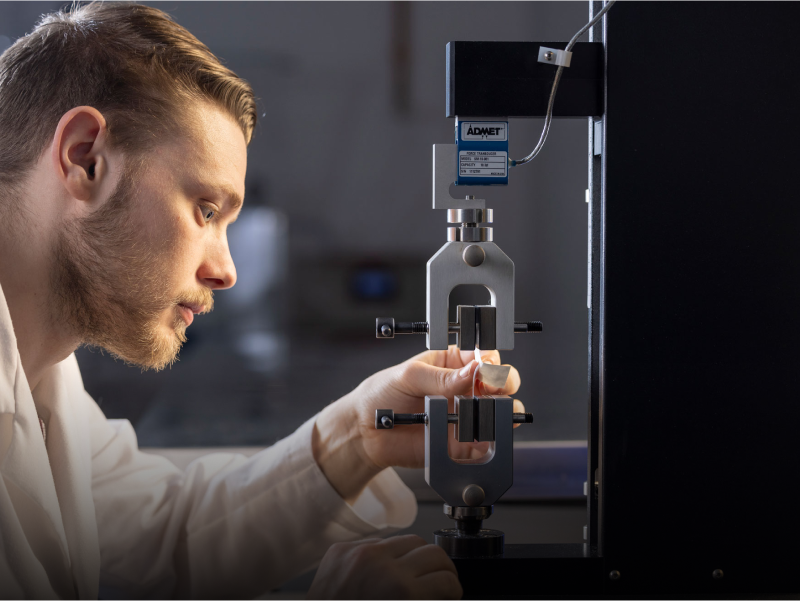

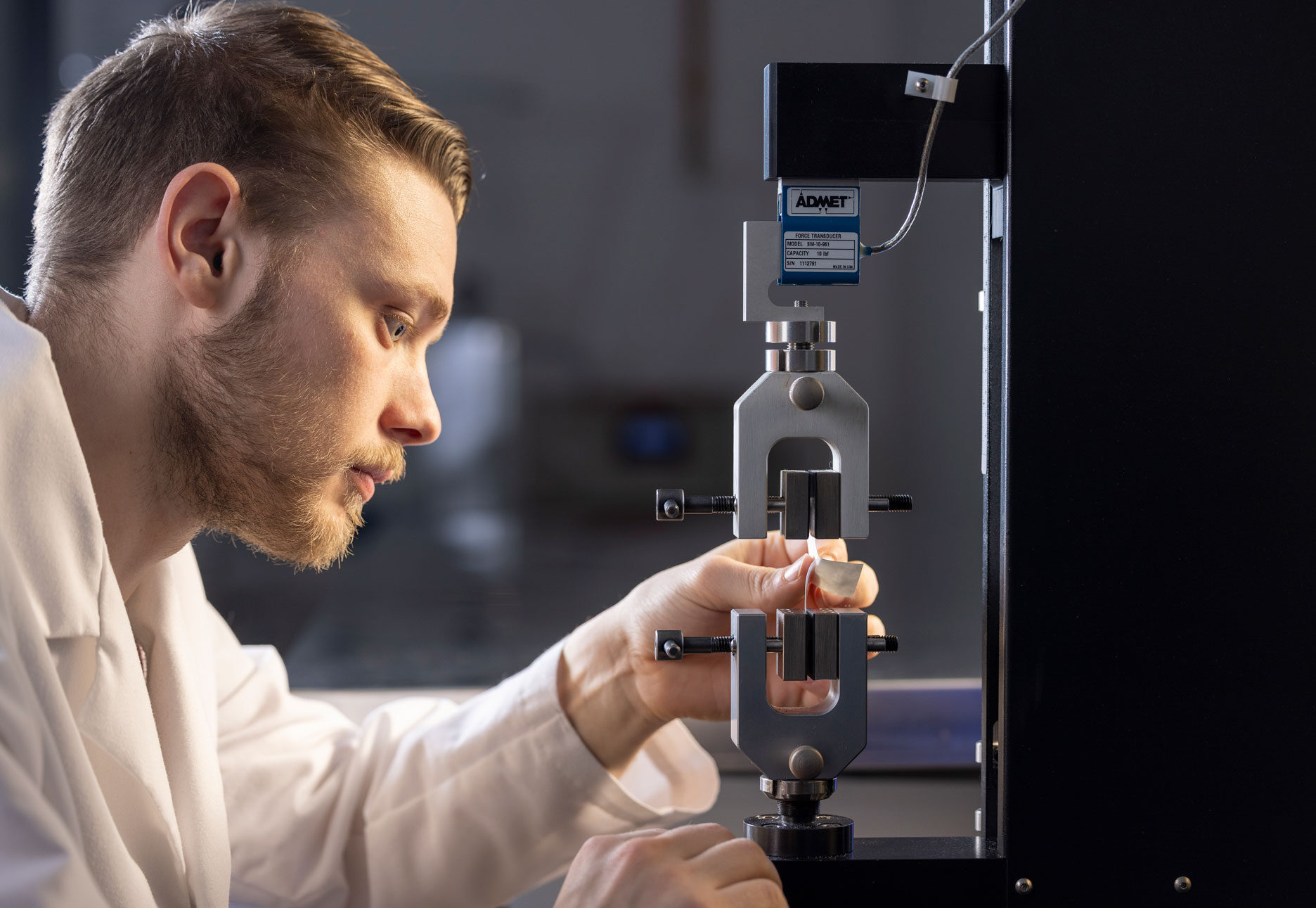

This ASTM peel strength test method is commonly used to measure the strength of adhesive bonds between two sealed materials, especially the closure seal of a sterile barrier package, such as a pouch or tray. The test is conducted by first cutting a 1″ wide specimen from the package. The specimen is then inserted into the jaws of a test stand such as an Inston, with one half of the material in the top jaw and the lower half of the material in the bottom jaw. The test stand then automatically moves the opposing jaws apart, causing the seal between them to peel apart at a constant rate of speed. A load cell measures the force required to fully separate the seal.

Industry Application

ISO11607 requires that sterile barrier seals maintain a minimum specified seal strength. The minimum seal strength specification is developed based on the capability of the sealing process when using worst case sealing parameters, as determined by Operational Qualification (OQ) and Performance Qualification (PQ) validation activities. The minimum seal strength specification is then translated to production as an important part of quality control and monitoring of production processes.

Seal strength measurement can also be used to verify stability of materials over time, such as in shelf life validation studies. It can also be used to evaluate the efficacy of a sterile barrier system through the rigors of sterilization, distribution and storage. Seal strength is also an important tool when considering human factors such as the ability to open a seal aseptically.

Frequently asked questions

What is peel strength testing per ASTM F88?

Peel strength, commonly known as seal strength, is a test method that covers the measurement of the strength of seals in flexible barrier materials. This test method measures the force required to separate a test strip of material containing the seal. It also identifies the mode of specimen failure.

How is peel strength testing performed?

Peel testing is performed by cutting a 1-inch strip on the seal of a sterile packaging system, attaching it to the peel strength machine which slowly pulls apart the seal while measuring the tensile load and the amount of separation of the grips.

Why do we need to consider the amount of force it takes to open a package?

"When the end-user peels open a package to aseptically present a device, a package that opens too easily may cause that user to question whether the seals were fully intact, and ultimately discard the device for patient safety reasons. On the flip side, a package that is too difficult to open may result in delamination, tearing, or fracturing upon opening, rendering it impossible to aseptically present the device without contaminating it.

Furthermore, package seals are also responsible for keeping the packaging intact through the rigors of sterilization, distribution, handling, and storage, until the point of use or expiration date. Seals that are too weak may be susceptible to premature opening during transportation (i.e. heavy devices bouncing around in a package may force the seal open from the inside), or long-term storage (i.e. products on a warehouse shelf for months or years), or from other stresses imposed during the finished product’s life cycle."