Microbial Ranking Testing for Porous Packaging

Microbial Ranking, often known as microbial ingress testing, per ASTM F1608 measures how effective porous material is in preventing airborne bacterial penetration for use in sterile medical devices. This test is particularly crucial because while data is available for medical grade Tyvek™, variations from converters’ coatings and aging effects often are undocumented and could pose a risk to package integrity.

Industry Application

ISO 11607-1, Section 5.2 states, “Porous materials shall provide an adequate microbial barrier to microorganisms.” ISO/TS 16775 5.8.2 states that “All sterilizable medical packaging materials for SBSs need to provide an adequate microbial barrier.” Traditionally, MDM’s have used packaging supplier data sheets to justify out of performing microbial ranking on the porous material of their sterile packaging.

There has been a growing number of inquiries of MDM’s getting push back from assessors that are not accepting the microbial ranking data from DuPont following shelf-life/stability studies. Performing microbial ranking after shelf-life studies confirms that the porous component of the sterile barrier maintains integrity throughout the desired shelf life. Additionally, testing becomes necessary when there’s a change in the coating on porous materials, to ensure the change hasn’t compromised barrier effectiveness. Microbial ranking is also valuable during R&D stages when comparing different coatings for packaging materials.

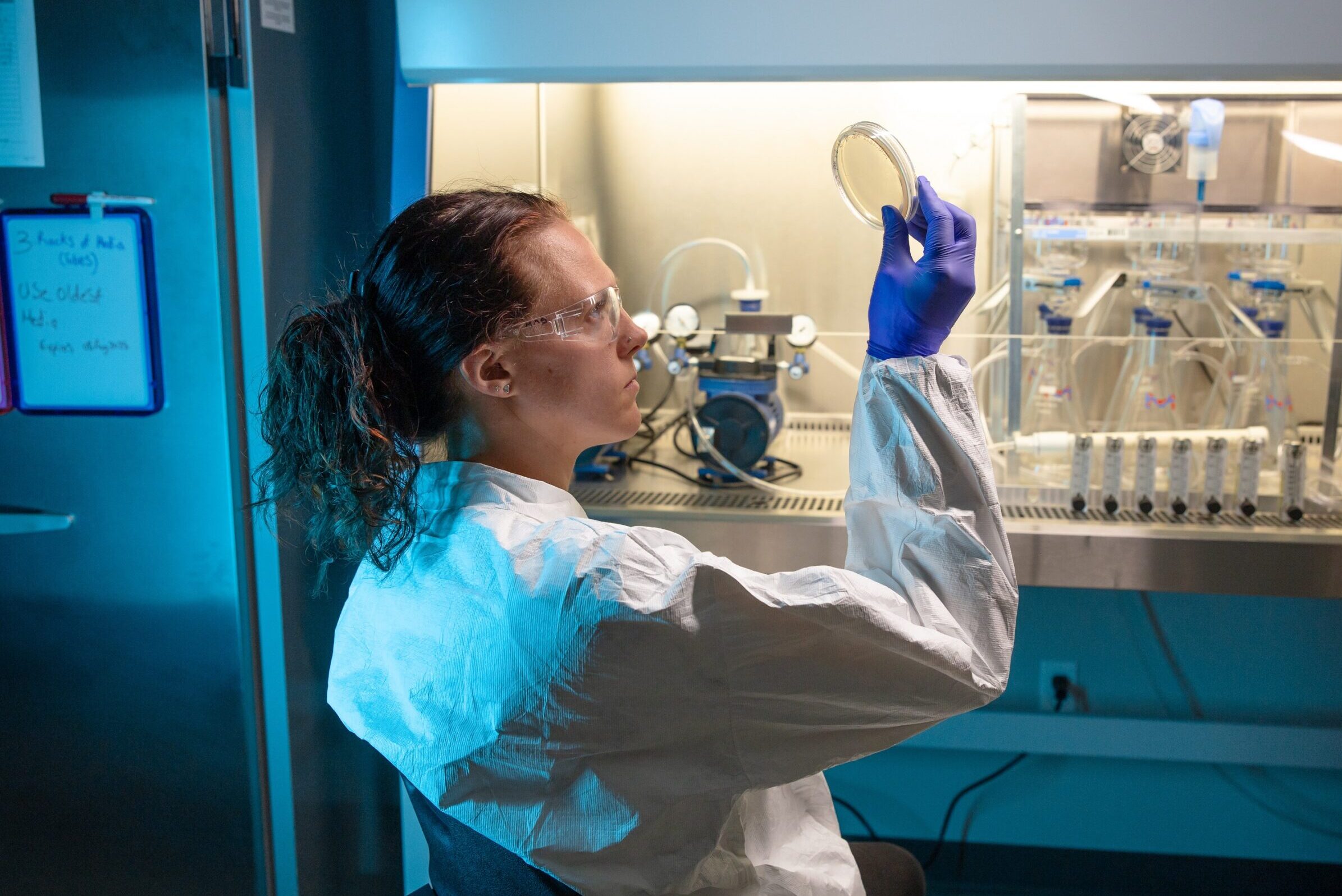

How is Microbial Ranking performed?

Microbial Ranking is performed per ASTM F1608 via the Exposure Chamber Method. With this method, there are two plating techniques that can be performed – Direct Plate and Blending.

For the Exposure Chamber Method, a cellulose nitrate filter is placed in each port. Four of the ports have a 47 mm porous sample layered over the filter. Two of the ports are control samples used to determine the actual exposure and validate the challenge run. The control sample is another filter. The challenge begins, and the Bacillus atrophaeus spore suspension is aerosolized into the chamber while a vacuum pump draws the bacteria through the samples onto the filter. The exposure period lasts for 15 minutes.

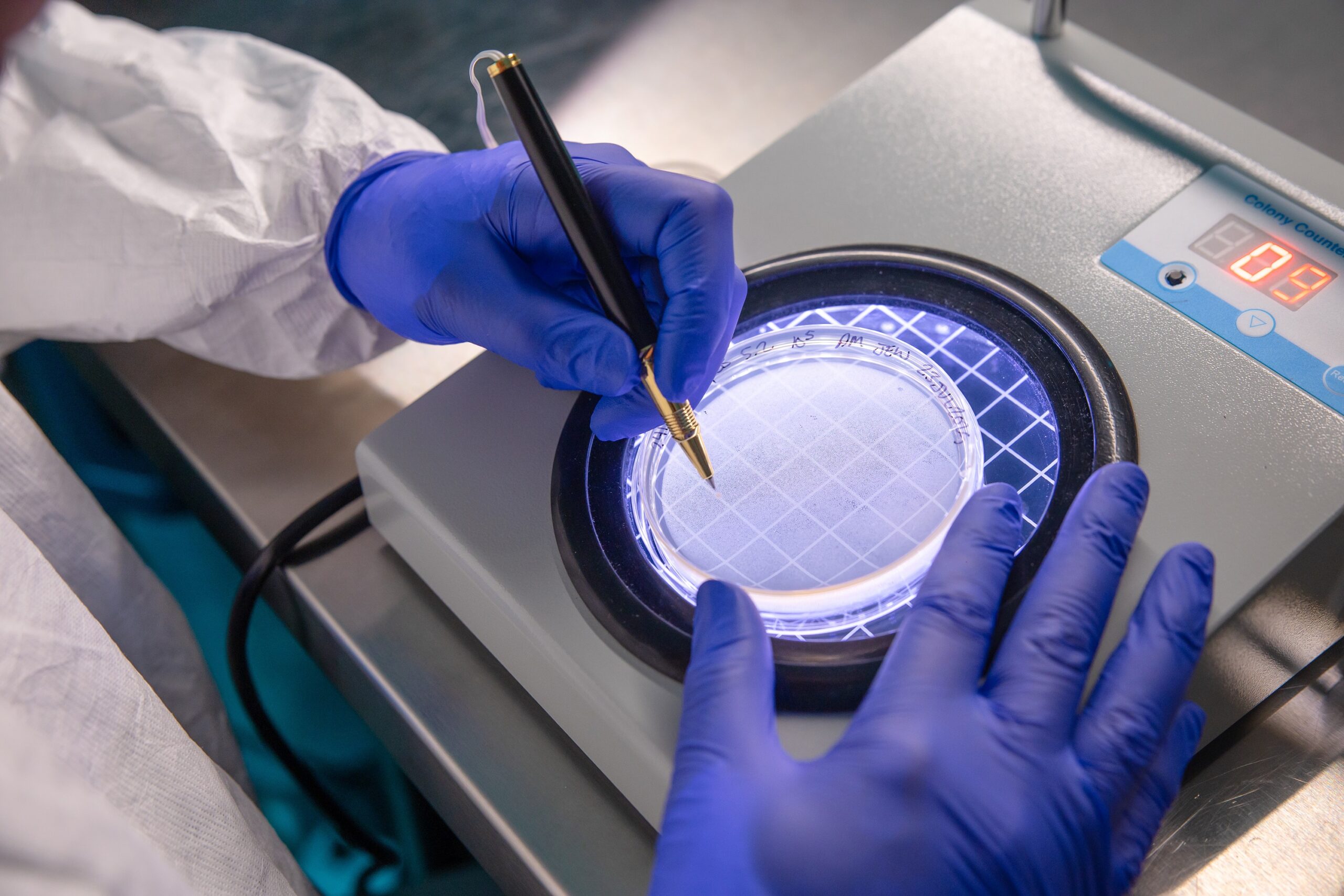

For the Direct Plating technique, each porous sample is removed, and the test filter is placed onto an agar plate with media. For the Blending Plating technique, each porous test sample is removed, and the test filter is blended in sterile water, diluted, and pour-plated. For both plating techniques, the positive control filters are blended, diluted, and pour-plated while the negative control filters are placed onto an agar plate with media. The last step is placing all plates in the incubator. After 24-48 hours, the number of bacterial colonies are counted and entered an equation to obtain a “log reduction value” (LRV).

FAQ's

When should I perform Microbial Ranking?

After shelf-life/stability studies or when there is a change in the coating on porous materials for sterile packaging. Microbial Ranking is also valuable during R&D stages when comparing different coatings.

What does microbial ranking do?

Microbial Ranking per ASTM F1608 measures how effective the porous material of sterile packaging is at preventing airborne bacterial penetration.

Which methods of microbial ranking does PCL use?

PCL uses the Exposure Chamber Method and utilizes both Direct Plate and Blending plating techniques per ASTM F1608.

Which plating method should be used?

a. When testing material like Tyvek which is known to have a higher LRV, the Direct Plate technique is utilized. When testing less robust materials like medical grade paper, the Dilution Plating technique is utilized. With this plating method, there’s a better chance of getting a countable plate, which will allow for a more accurate assessment of the test material.

What is a typical Log Reduction Value (LVR) for Microbial Ranking?

Achieving a 4 to 5 LRV is common for Tyvek. Medical grade paper falls between 1 to 3 LRV.

Do my samples need to be sterilized for microbial ranking testing?

Yes, you will want to ensure your samples are sterilized prior to the test. Heavy bacterial contamination can interfere with the test and the result, so it’s best to use samples with a very low bioburden. It’s ideal to use the sterilization method that will be utilized during commercial production, but any sterilization will do.

Is microbial ranking required by the FDA?

Yes, it is required. ISO 11607-1, Section 5.2 states that “Porous materials shall provide an adequate microbial barrier to microorganisms.” ISO/TS 16775 5.8.2 states that “All sterilizable medical packaging materials for SBSs need to provide an adequate microbial barrier.” However, many MDMs are using existing DuPont data to justify out of performing microbial ranking on the porous material of their sterile packaging.

Why is microbial ingress testing performed?

Microbial ingress testing is necessary to confirm sterile barrier integrity, especially after packaging changes or aging, aligning with FDA and ISO 11607 expectations.

What should my sample size be for microbial ranking?

Ultimately your sample size should be risk based. ASTM F1608 states that the minimum sample size for a given material is two. However, many MDM’s will select sample sizes corelated with other sterile packaging or microbial tests.

Should microbial ranking be performed after every interval for aging studies?

Yes.