As we near the close of 2023, the tried-and-true ASTM F88 standard gets a new revision. First, for those who are unfamiliar, ASTM F88 is a standard that explains how to perform a test method for seal strength. Seal strength testing allows packaging engineers to design packages with desired seal strength, verify seal strength specifications at different life cycle stages (in production, after sterilization, after transportation, and after long-term storage), and establish control & monitoring programs for quality assurance over time.

How is Seal Strength per ASTM F88 Performed?

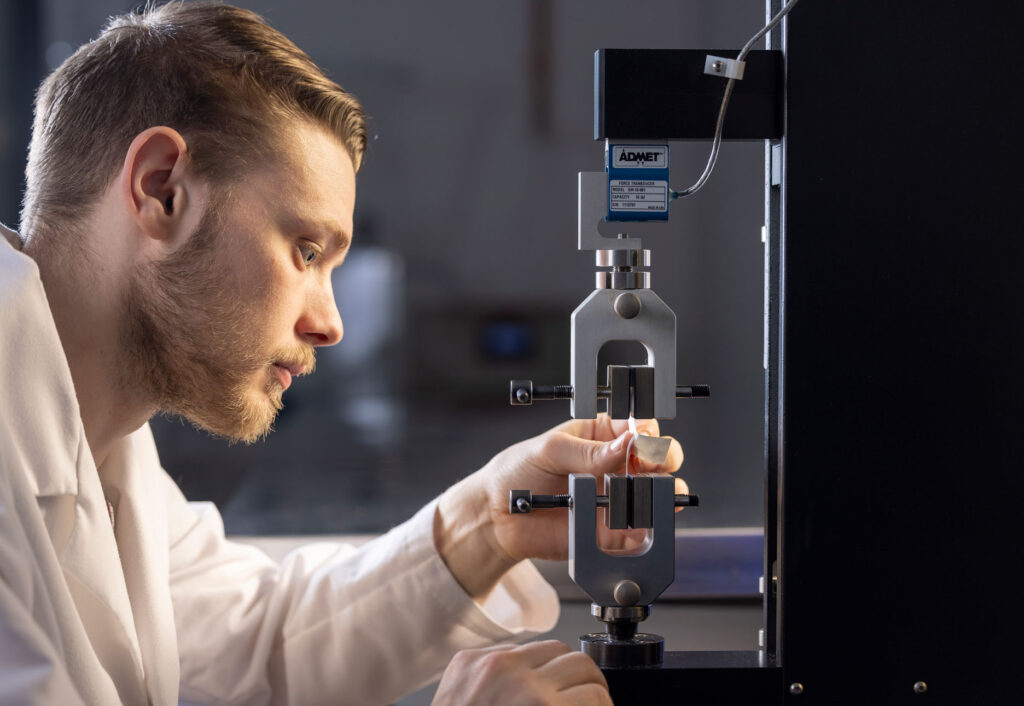

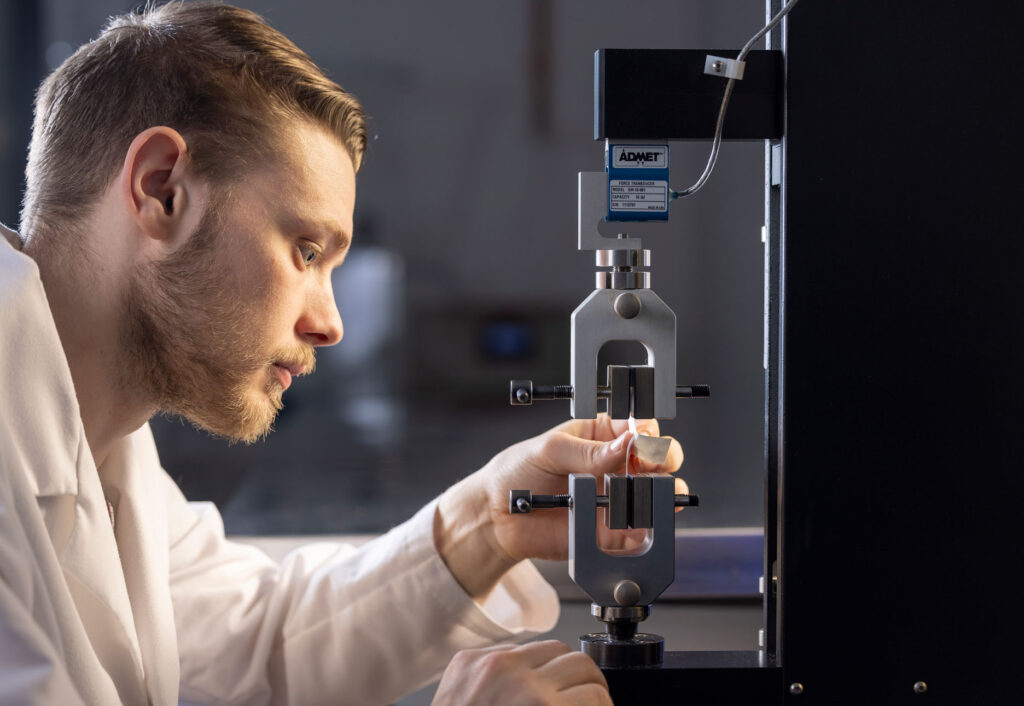

For this test, we take a 1-inch wide cut from the seal, clamp the test specimen into the jaws of our peel test stand, and then use our peel test stand to pull the seal apart. The peel test stand uses a gauge to measure the amount of force that is required to peel apart a seal. Typical seal strength is between 1 to 2 pounds per inch but should be uniquely established for the application.

What Determines Seal Strength?

PCL’s preferred approach is to first optimize your sealing process, and then apply process engineering statistics to OQ test data. Results can be used to calculate a lower-bound and upper-bound specification limit using the one-sided tolerance limit calculation, which considers your desired confidence & reliability (allowing you to link it back to your risk assessment). Packages with artificially weak seals may then be created and subjected to transit testing and aging validations, which demonstrate the capability of worse-case packages to maintain integrity. Likewise, packages for usability studies can be created to match routine conditions or artificial extremes. Of course, your production PQ study will demonstrate repeatability and reproducibility under expected routine conditions.

What Changed in the Latest Revision?

This latest revision included a major change in scope to include testing between a Flexible material and another Semi-Rigid or Rigid material whereas the previous revision only included guidance in testing between a Flexible material and another Flexible material. As such, the latest revision includes clarification as it pertains to setup and test procedure guidance to Techniques A, B, and C for the newly introduced material types with updated diagrams and tables throughout the standard. For full details on the new standard please visit the ASTM website to purchase the latest revision and consider joining the F02 committee to become more involved.

How Does PCL Ensure Testing is Being Performed to the Latest Revision?

PCL takes a two-pronged external and internal approach to keeping up with the latest testing standards in the industry. Externally, PCL is active in ASTM F02 and D10 committees that regularly meet to discuss the testing processes and verification requirements for medical device packaging. “My responsibilities are to make sure the lab is adhering to all these new standard revisions so that our clients have confidence their packages meet regulatory testing requirements,” says Matt TerBush, Senior Laboratory Packaging Engineer. Internally, PCL has constructed a Standards Working Group team that springs into action when a new revision is released. The team reviews the revision of the standards from a technical, quality, and operational perspective to assess any gaps in various laboratory SOPs (Test Method Work Instructions, Equipment Operating Instructions, etc.) and re-train our Lab Technicians on the changes.

Rest assured that PCL keeps up with the standards and please reach out if you have any questions about the F88 revision as we’d be happy to connect you with someone on our quality team!