When it comes to medical device packaging validation, one of the critical steps is determining your sample size. This decision has an impact not only on the cost and efficiency of your validation process, but also the confidence you can have in your results. ISO 11607 does not directly dictate how many samples you need to test, leaving it up to the packaging professionals to decide and ultimately justify. To help you navigate this process, we had our Senior Packaging Engineer, Sean Coast, answer some common questions regarding sample size.

So, with no official ISO 11607 guidance, where should you start?

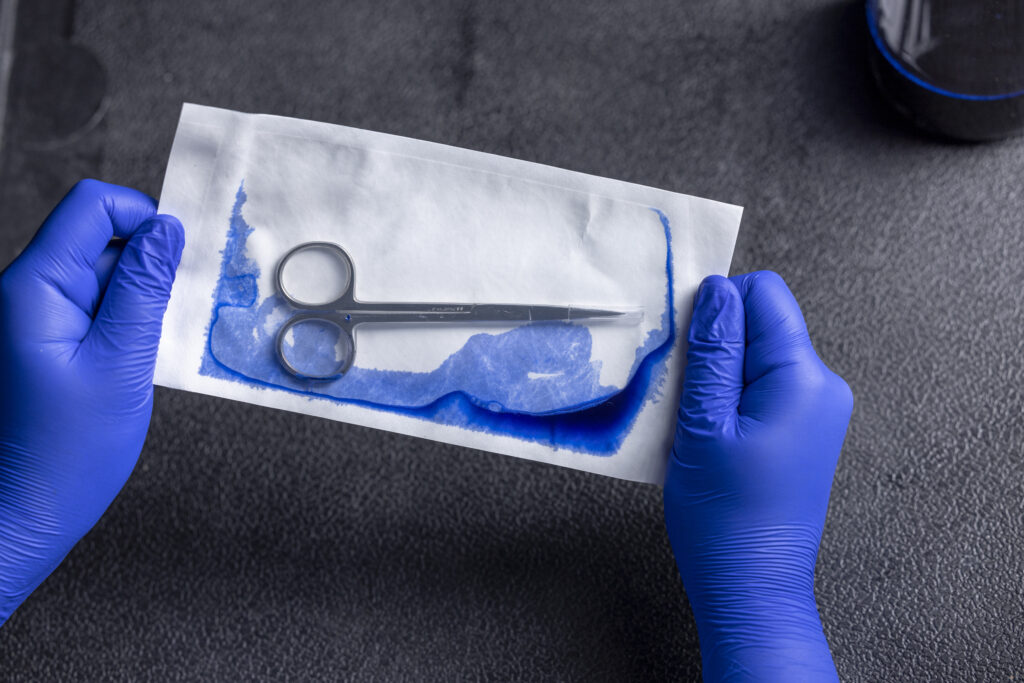

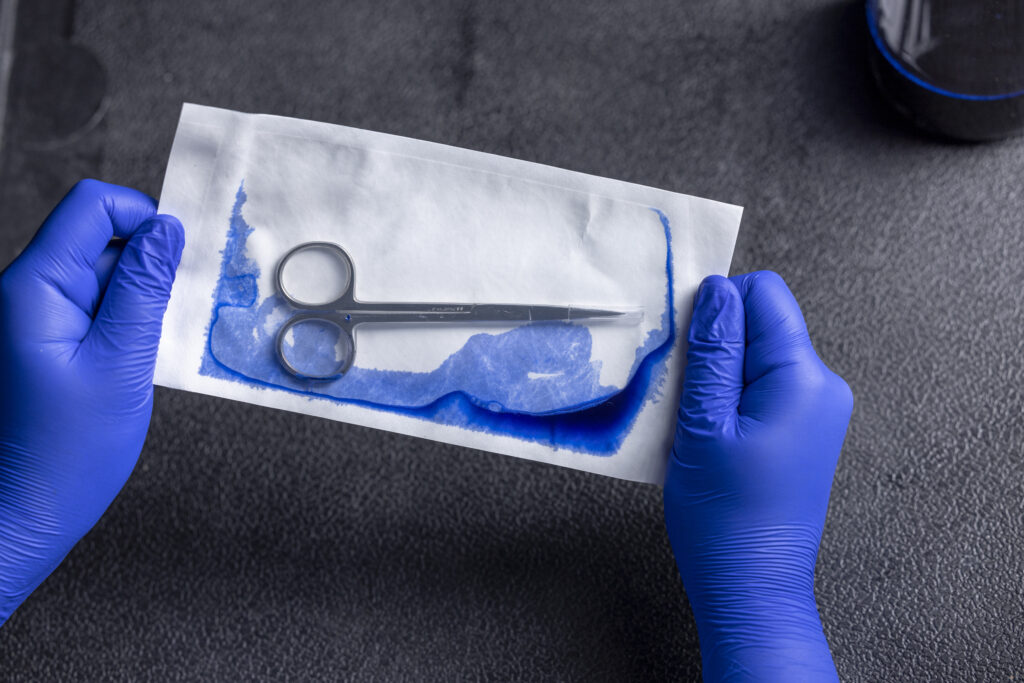

Start with knowing the ins and outs of your packaging system. Your packaging design will be one of the greatest influences on the number of samples needed. There are certain tests, dye leak for example, that are more destructive to trays than they are to pouches, limiting the reuse of trays. Understanding how your specific packaging design will be affected is important.

What factors will influence sample size?

This is where your PFMEA and DFMEA assessments will come into play. Along with the specifics of your medical device and your packaging design, these assessments will point out specific details that will determine your sample size. Here are a few example questions that you should be asking yourself during this step:

- What class is my device?

- What is the use environment?

- What is the intended function of this design of component?

- What happens if said failure occurs?

The answers to these questions will be important, determining factors for your sample size.

What role does risk play in sample size decisions?

A significant one! Medical device manufacturers (MDMs) need to decide how conservative they want to be. A common standard is 95%/95% confidence/reliability. But some MDMs will choose a more cautious 99%/99% while others, relying on previous data or simply accepting more risk, may go with 90%/90%. It all comes down to your risk tolerance.

When in doubt, 95%/95% is the way to go.

What is the difference between attribute and variable samples?

Variable sample groups are used for test methods that will produce measurable data, such as seal strength testing. Attribute sample groups are used for test methods that result in a pass or a fail, such as dye leak.

What are some common sample size roadblocks?

Funding is a common roadblock. Medical devices are expensive, so creating enough devices for testing can be a financial challenge.

Also, packaging validation is sometimes an afterthought, so timing becomes an issue. Companies focus heavily on designing and validating the device itself, and packaging doesn’t get the attention it needs until late in the process. But it’s important to remember that without validated packaging, a product can’t go to market.

How can companies overcome these hurdles?

Regardless of your budget or risk tolerance, you must go through the packaging validation process. If you’re working with limited funds, we recommend going with 95%/95% confidence/reliability. Most importantly, start planning early. Incorporating packaging validation into your project timeline from the start can prevent costly delays later.

Is there such a thing as too many samples?

Yes and no, everyone’s favorite answer to a question. While more samples can give you increased confidence in your results, you generally don’t need to go overboard. In most cases, a standard sample size that meets 95%/95% confidence/reliability is more than sufficient.

Can you use the same samples for multiple packaging validation tests?

This goes back to what we discussed earlier with package design. There are certain packaging types that can be tested twice, however, there are risks involved. For example, when going through transit testing, you could perform a bubble leak test and seal strength test on the same sample. But the bubble leak test could damage the sterile barrier and cause a failure during seal strength testing where maybe there wouldn’t have been one. Going this route can give you untrustworthy results.

This could lead to the need to perform extra testing, which will delay your timelines and increase the overall cost of your project. We recommend avoiding the risk and investing your valuable time and money in different sample groups. More often than not, the extra samples will be less expensive than running additional testing and it’ll help keep your project timeline on track.

Key Takeaway

Even without direct guidance from ISO 11607, MDMs can approach their sample size decision with confidence. Knowing your device and packaging design, risk tolerance, and the necessary test methods will guide you in making informed decisions.