Test Method Validation

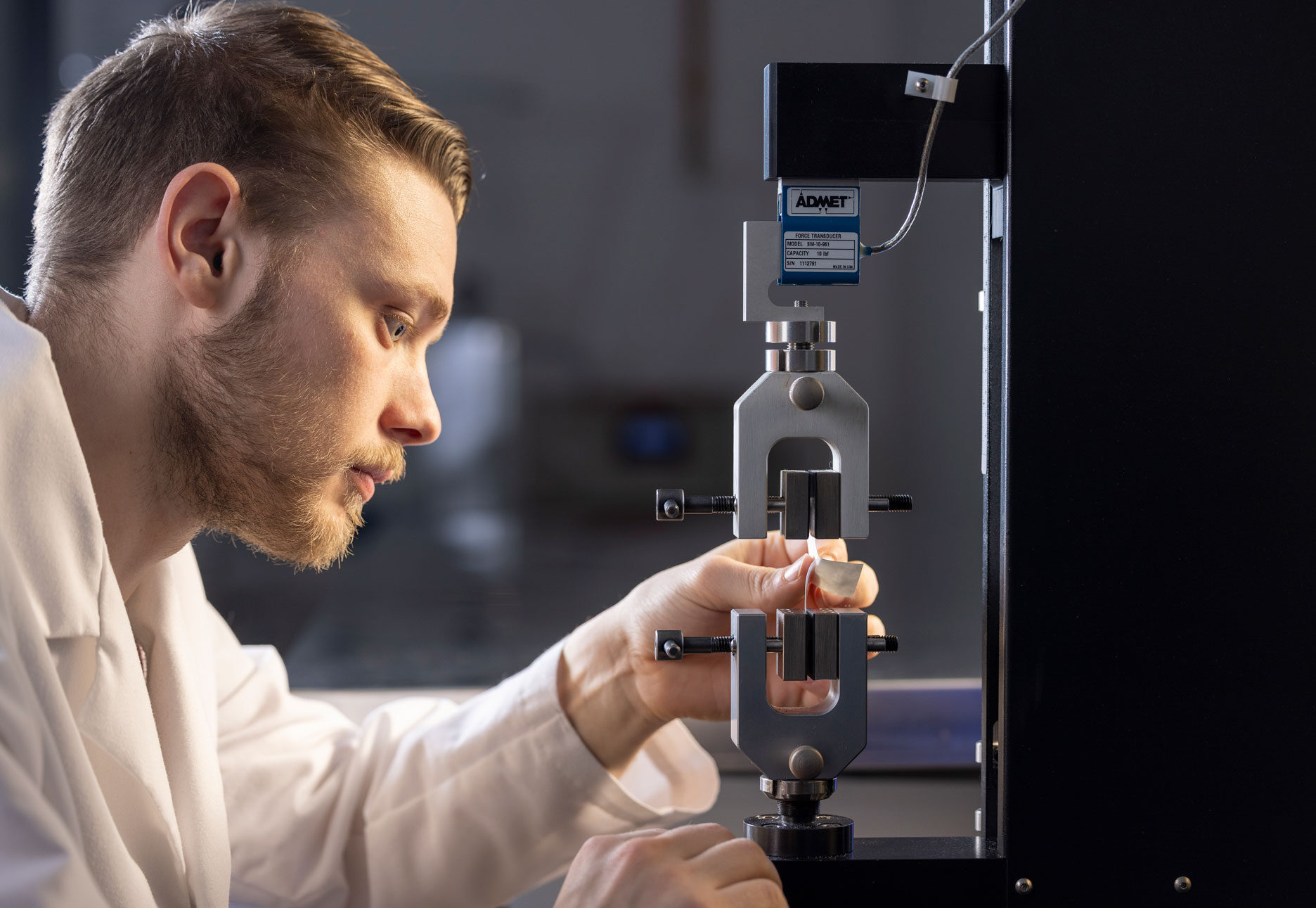

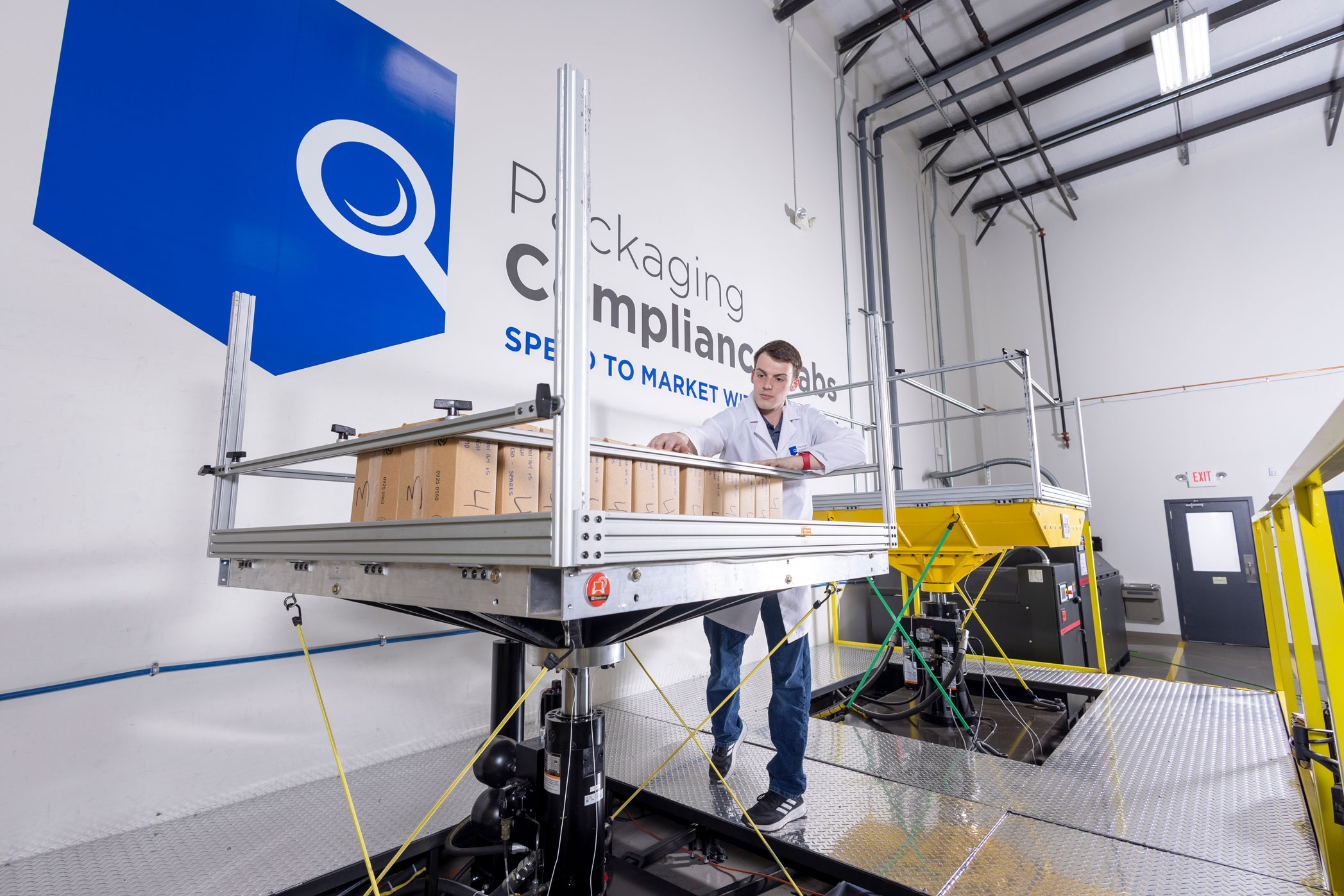

ISO 11607 requires that test methods be properly validated, including test methods used in the clean room environment for production quality control. Our engineers will develop a test method validation strategy for your application, author a protocol, travel to visit your facility to train employees, and help oversee the validation efforts. Having a third-party involved in this critical part of the production process can help ensure that your test results are accurate and reliable.

4 Pillars of Packaging Validation

Visit Resource >