Feasibility / Proof of Design Concept

Vetting the packaging design concept (yours or ours) is a critical component of successful validation. We perform a series of tests to:

- Establish viability of the existing design, and

- Identify potential failure modes for the system. This is a great tool to gain confidence before you invest in tooling and inventory.

Who Feasibility Testing is For

Our proof of design concept and feasibility service is for medical device manufacturers in the process of creating a new packaging design.

What Is Feasibility Testing?

We assemble a small number of functional prototypes of the proposed product-packaging system design concept. These prototypes are then subjected to heightened-severity drop & vibration stress tests to challenge the design, followed by visual inspection & package integrity testing. Results can be used to inform the engineer of potential design or performance-related risks, so that those risks can be mitigated in advance of a formal transit validation study. Our data suggests that as many as 30% of transit validation studies have unintended outcomes – which is why performing feasibility testing early in your design & development project is so critical to downstream validation successes.

What's Included in Feasibility / Proof of Design Concept

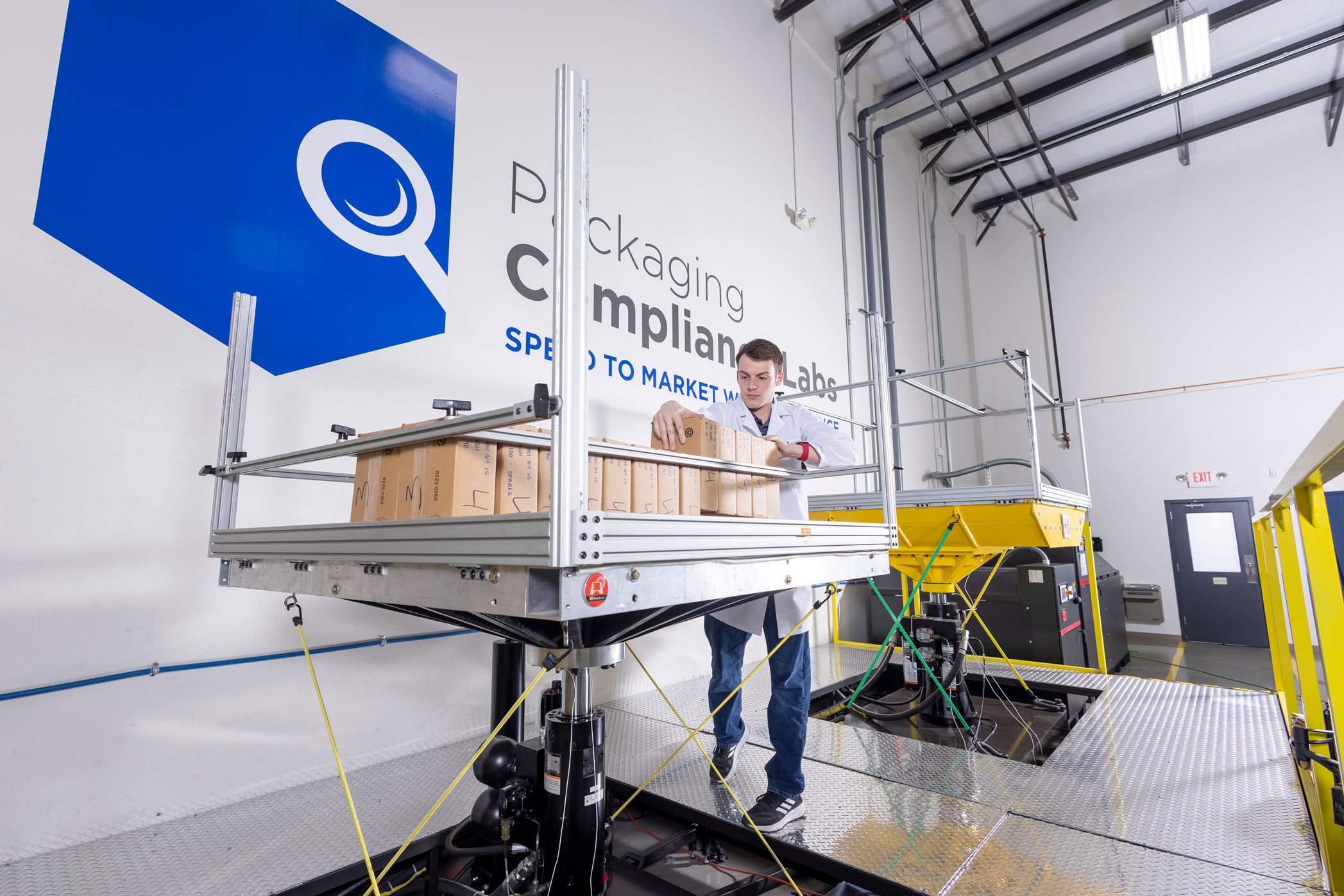

Transit simulation testing

Visual inspection and sterile barrier integrity testing

Engineering test report, with findings and observations for all tests

Findings meeting with your team to review results and actionable recommendations