Growing Pains

Packaging Compliance Labs uses lean practices (like 3P) to support our commitment to short lead times and quick turnaround for all clients, no matter how big or small the project.

We recently demonstrated that commitment when we doubled our lab space. The additional space allows room to grow, and several new pieces of equipment, including two accelerated aging chambers, a new vibration table, and new compression and drop testers, are scheduled to land within the next month. We also recently added talented team members to our technical staff to help keep up with growing demand.

We view the proactive identification of pain points as part of our continuous improvement focus. It also makes getting work done more efficient and more rewarding. When we doubled our space, it was the perfect chance to look at inefficiencies in our receiving process.

Apply 3P

This is where 3P comes into play. 3P is a lean technique that stands for Production Preparation Process. The goal of 3P is to design a process resulting in the least possible waste. In our case, we knew that our receiving station was going to be relocated to our newly expanded space. The 3P method allowed us to view receiving as a blank canvas. We could step out of the preconceived confines of our existing layout to come up with something better.

To start the event, we defined a scope of work and clear definition of the outcome we wanted to achieve. With any lean project, adding specific targets and quantifiable improvements is important. We then assembled a cross-functional team that could view receiving from different perspectives.

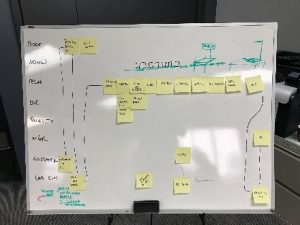

As a team, we first assessed the new receiving space. We taped the floor, stacked empty boxes to represent workstations, carts and made diagrams to map out a vision for the layout. We even set up a simulated receiving process to bring our thoughts to real life. We tested the process from beginning to end multiple times. Each time, we brought our simulated shipment through the receiving department steps. From incoming inspection to photos, weighing and measuring, labeling, preparation and queuing, we looked for hiccups. And similarly, each time, we found improvements to streamline efforts and maximize results.

Example Swim Lane Diagram to Map Process

Great Results

A sign of any good event is when the team is actually excited about implementing the changes. We eagerly wrote down the new process and assigned action items. Outcomes included the introduction of designated drop-off zones for UPS/Fedex, a new weighing and measuring station, and lots of other updates. We also built in new smart steps such as marking items for transit simulation and calculating target compressive loads.

At the end of the day, what matters most to our clients is getting their projects done quickly, accurately and reliably. This successful 3P event and other Kaizen events in the pipeline ensure our continued focus on our customers’ definition of value. Three cheers for 3P!