In the race to get sterilized medical devices to market, it’s crucial to be efficient during every step of the process. One critical factor that can make or break your timeline during transit testing is how you determine and test your worst-case packaging configurations. Get it wrong, and you risk delays and costly retesting. Get it right, and you set the stage for a smooth, efficient path to validation.

In a previous post, we took a closer look at the concept of worst-case configurations. Including what the term means in the context of medical device packaging validation, how it aligns with the requirements outlined in ISO 11607, and a few examples. In this post, we’ll take that discussion further by diving deeper into the reasons why clearly identifying and rigorously testing your worst-case configuration is a vital step in ensuring product integrity and patient safety.

First, Let’s Recap!

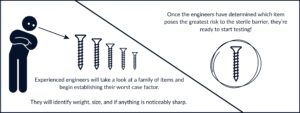

When it comes to design verification, we must ensure that whether a medical device is going through transit or simply sitting on a shelf in a hospital, that the sterile barrier will remain intact. To properly test the integrity of the package, experts will test the worst-case configuration from the intended product and package combinations. Worst-case is considered the most challenging device, package system, or combination of those items to get through testing.

Simply put, it’s what is most likely to fail. When it comes to sterile packaging, the component that creates the greatest risk to the sterile barrier would be considered your worst-case. For example, say the heaviest item in a product family puts the most strain on the packaging. If it passes transit testing, we are able to infer that the lighter items will also pass. This approach eliminates the need to test every individual item in the same device family.

If it’s difficult or impossible to define a single worst-case testing option, engineers will often utilize a “bookend” approach. This just means that you’re testing both ends of the risk spectrum, such as the largest and smallest devices or configurations. If both sample sets pass testing, it can be assumed that everything in between will also pass.

So, now that we’ve recapped what worst-case is, how do we go about determining an accurate configuration and why do we use it? We sat down with our Vice President of Quality, Ryan Ott, to discuss everything you need to know to confidently approach your worst-case configurations.

Three Most Common Worst-Case Factors

- The weight of the device

- If the device has sharp features or a rough abrasive coating

- The size or geometry of the device

Most often the largest, heaviest, or sharpest objects will pose the greatest risk to package integrity. But that’s not always the case! Taking a step back and looking at the bigger picture is helpful when determining your worst-case configuration.

Inaccurately capturing your worst-case factor is one of the most common pitfalls and will only lead to more testing. This is why our experts recommend considering all of your options before finalizing your worst-case configuration. At first glance, something that looks like it might poke through the package could possibly be mitigated with a tip protector. Eliminating that risk would leave the weight of the device as the most accurate worst-case factor.

Feasibility testing is a helpful resource when you’re stuck trying to figure out your worst-case configuration. Feasibility testing allows you to test multiple packaging designs to find the right one for your specific packaging needs. Keep your project timelines on track and stay on budget by utilizing feasibility testing and your professional experience to accurately establish your worst-case configuration.

There is no one size fits all protocol for determining your worst-case packaging configuration so it can feel ambiguous at times, maybe even a little intimidating to someone who is early in their career. ISO 11607 Part 2 offers us some guidance on how to approach worst-case, but it can still be a tricky process. This is why it’s important to approach each case logically and with a complete understanding of your packaging systems and devices.

Why Do We Test Worst-Case Configurations?

You might be wondering, why take the risk? Why not test every single item to cover all possible scenarios? The reality is, that’s neither practical nor necessary. When the worst-case packaging configuration is properly identified and tested, you’re intentionally pushing your packaging design to its limits.

From a transit testing perspective, this means simulating conditions that go beyond what a package would typically experience. It’s like turning up the intensity on the bumps and vibrations it might face on a FedEx truck. By focusing on the most challenging scenario, you gain confidence that the rest of your product line will be well protected without wasting time and resources on redundant testing.

“The top three reasons for testing to the worst-case are patient safety, cost effectiveness, and time,” says Ott.

Patient Safety

Patient safety is embedded in the fiber of what we do in the sterile packaging industry. The main goal with package testing is making sure that a sterile barrier system remains intact until its time of use.

Cost Effectiveness

It’s no secret that medical devices are expensive to produce. This means that supply is limited for testing, and we need to be smart with how we test. Requiring a larger sample size for multiple products in your family would mean a higher price for the manufacturer, longer project timelines, and ultimately, a higher price for the end consumer. The ability to get results by testing the worst-case only helps to keep costs down.

Time

Speed to market is important to medical device manufactures (MDMs). The reality is that patients often can’t afford to wait for the lifesaving medical devices they need. If every configuration had to be tested, labs would quickly reach capacity, leading to significant delays in delivering test results. By focusing on worst-case factors, we’re able to narrow the testing scope, ensuring that validation is both efficient and timely, without compromising the integrity of the device.

Key Takeaway

Identifying and testing the worst-case configuration is crucial for efficient and effective sterilized medical device packaging validation. Focusing on the worst-case configuration saves time, reduces costs, and helps ensure patient safety and package integrity. A clear, logical approach backed by standards like ISO 11607 helps avoid delays and unnecessary testing.

Still have questions? Reach out to speak with one of our packaging experts!