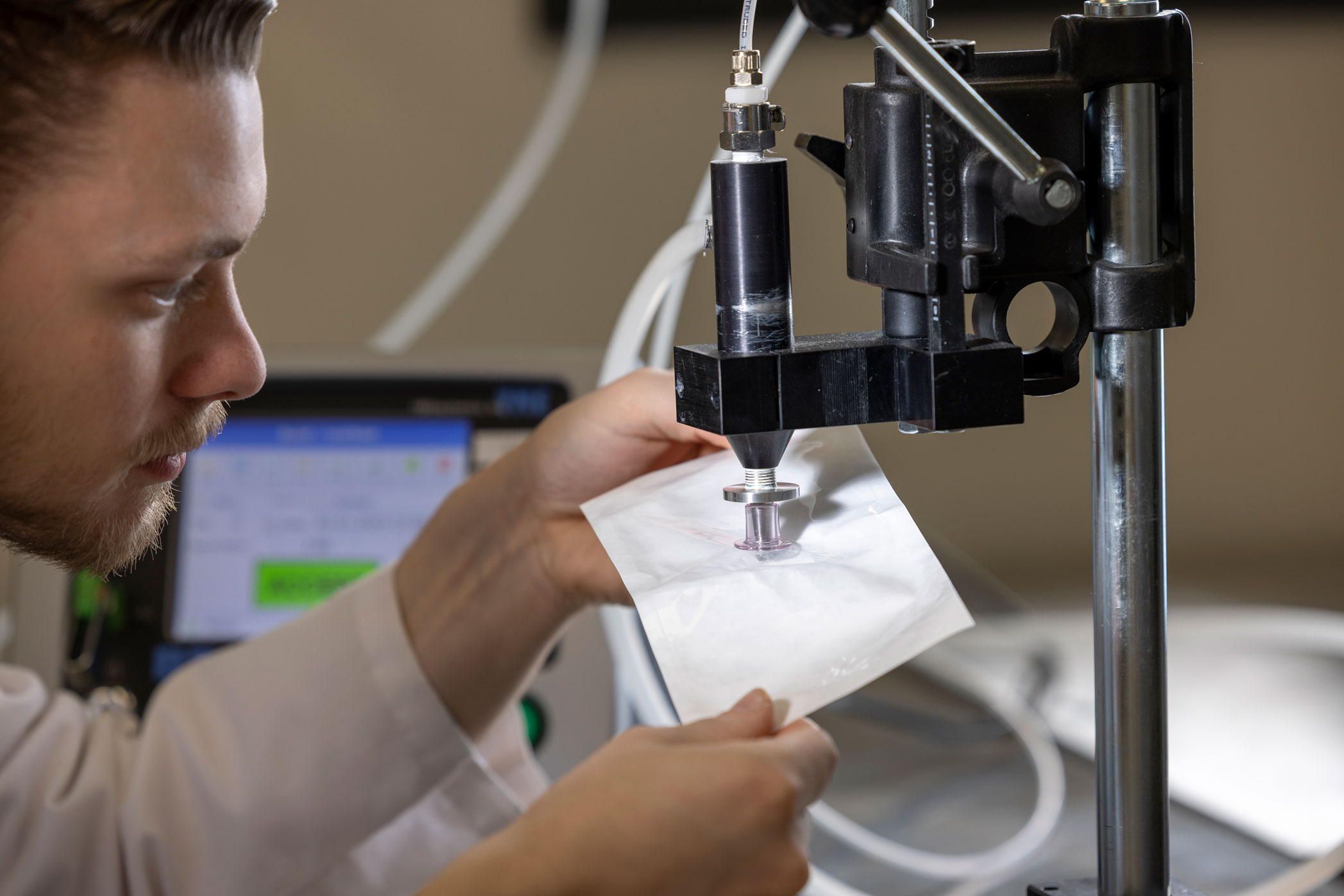

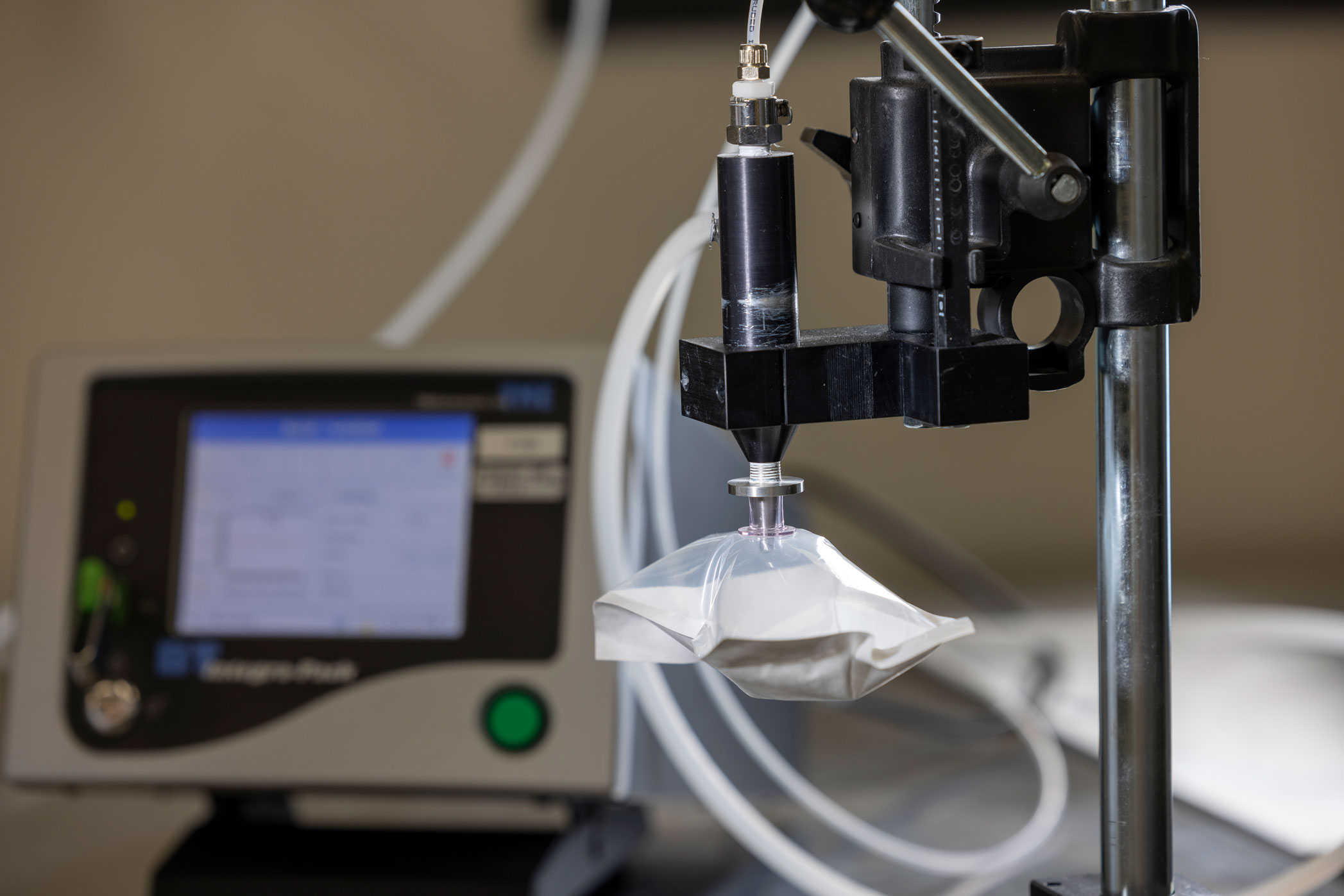

Burst Strength Test

To perform a burst strength test, a package is inflated with air until the package seals rupture. The internal pressure of the package at the moment of burst is measured. One technique for conducting a burst test is to otherwise not constrain the package while it is inflating, as described by ASTM F1140. Some large packages benefit from being constrained between two rigid plates while the package is being inflated, as described by ASTM F2054. Both methods are suitable for measuring seal strength.

ASTM standards provide for several test methods for burst testing, including dynamic, static, creep, and creep to fail tests. These tests are used to measure the strength of medical device package sterile barrier systems as well as characterize which seal within a package system is the weakest.

Industry Application

Burst testing measures the pressure at which packaging will burst. It is important to note that this application is ideal for packages where you are making all seals, not just a closure seal. Some examples would be a thermoform tray or a form-fill-seal application.

Burst testing is typically more attractive for in-process testing because it is faster than other methods. A limitation to burst testing is the inability to trend seal strength of a specific package location over time. PCL has the ability to perform restrained and unrestrained burst testing.